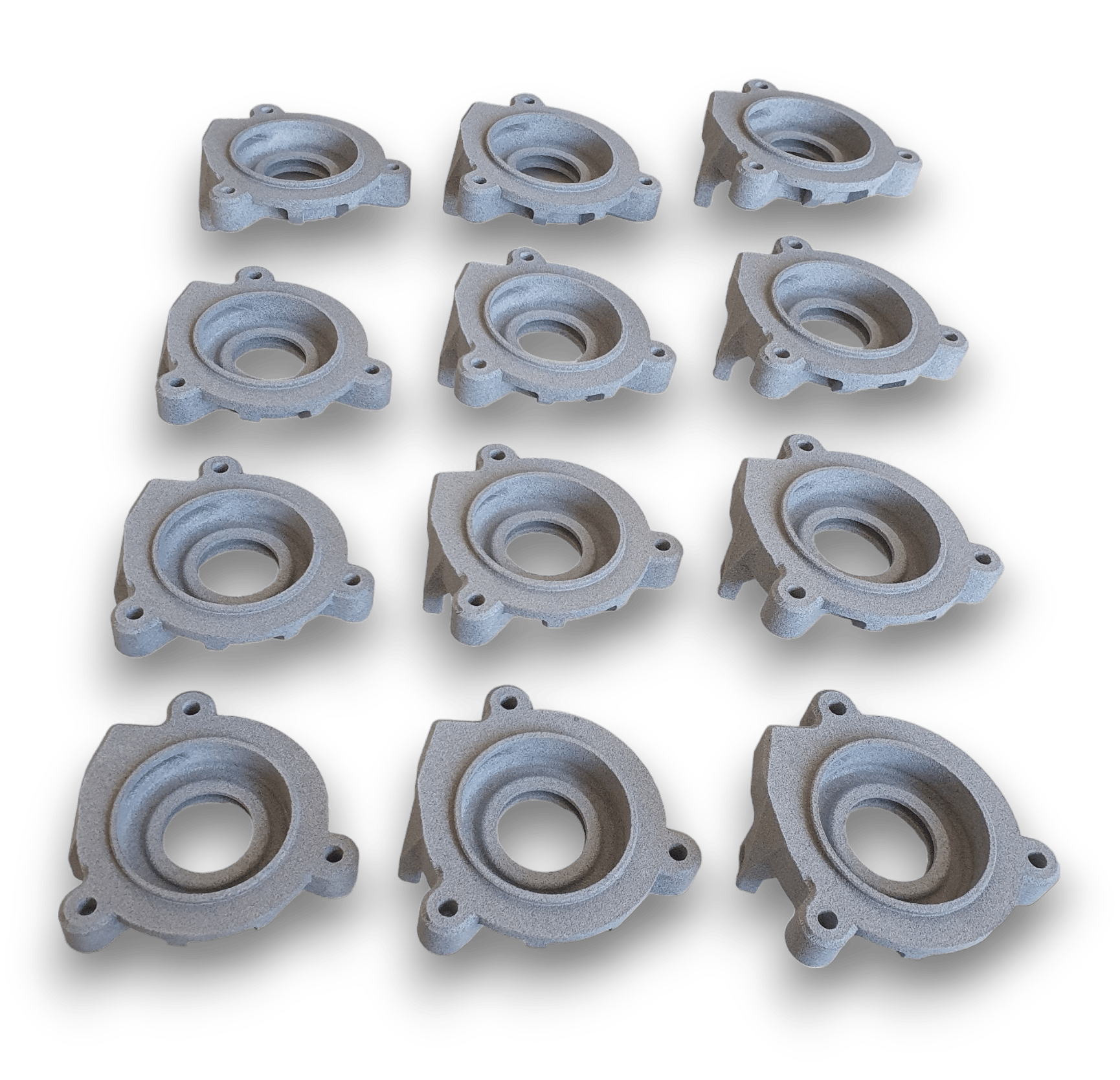

Multi Jet Fusion (MJF) is an exciting 3D printing process offering engineering grade material options with great overall properties. MJF allows you to produce more parts per day with continuous printing and fast cooling. Multi Jet Fusion offers an improved surface finish, more accurate features, improved mechanical properties and rapid build times.

Intrigued by Materials in MJF Printing? Explore our dedicated selection for in-depth insights into the versatile range of materials and their applications, enabling remarkable results in 3D printing with Multi-Jet Fusion technology.

-min.png)

Dimensional accuracy:

+/- 0.3% with a lower limit of +/- 0.3 mm

Build Volume Space:

380 x 285 x 380 mm (14.9" x 11.2" x 14.9")

Dimensional accuracy:

+/- 0.3% with a lower limit of +/- 0.3 mm

Build Volume Space:

380 x 285 x 380 mm (14.9" x 11.2" x 14.9")

Dimensional accuracy:

+/- 0.3% with a lower limit of +/- 0.3 mm

Build Volume Space:

380 x 285 x 380 mm (14.9" x 11.2" x 14.9")

Multi Jet Fusion (MJF) is an advanced 3D printing method that utilizes fine powder, fusing agents, and infrared light for high-precision outputs. By printing layer-by-layer, MJF ensures detailed, durable, and consistent components, making it ideal for industries demanding top-tier quality and intricate designs.